Addressing PHMSA requirements for Rupture Mitigation Valve Risk Analysis on Natural Gas Pipelines

Gain valuable insights from Curtis Parker, Principal Consultant at Dynamic Risk, as he shares his insights on meeting the requirements specified by PHMSA’s 49 CFR 192 regulations for conducting Rupture Mitigation Valve risk analysis.

What are the requirements in 49 CFR 192 for Rupture Mitigation Valve risk analysis?

Federal pipeline regulations in the United States (49 CFR §192.935(c)) require that operators perform a risk analysis to determine whether the use of Rupture Mitigation Valves (RMV), such as remote-controlled valves and automatic shut-off valves, may be efficient to add protection to high consequence areas for pipeline segments covered by 49 CFR Subpart O. In addition, regulations (49 CFR 192.935(f)) require that these risk analyses are certified by a senior executive of the pipeline operator on an annual basis.

In making that determination, these regulations require that an operator must, at least, evaluate the following factors:

- Timing of leak detection and pipe shutdown capabilities

- The type of gas being transported

- Operating pressure

- The rate of potential release

- Pipeline profile

- The potential for ignition, and

- Location of nearest response personnel.

Other requirements in 49 CFR 192 may also be relevant and applicable in a RMV risk analysis. For example, 49 CFR 192.634 has requirements for maximum valve spacing for RMV installed to isolate an HCA.

What are the challenges in performing a RMV risk analysis?

Federal regulations lack prescriptive guidance on how operators should assess whether RMV efficiently enhance protection in high consequence areas, beyond stating the minimum factors for evaluation. Therefore, a robust and defensible methodology is essential to demonstrate compliance with the regulation. An operator’s pipeline risk assessment model utilized for integrity management (as required by 49 CFR Subpart O), may not have the capability to satisfy this specific mitigative measure.

For example, an operator’s pipeline risk assessment model may not be configured to address the complexities involved in comparing consequence estimations for different valve closure responses following a hypothetical pipeline rupture. This type of analysis involves evaluating dynamic and time-based variables, including:

- Timing of valve closure and pipeline segment isolation

- Transient gas release behavior following a pipeline rupture and corresponding thermal radiation impact area from an ignited pipeline rupture

- Time-dependent estimates of damage to property from secondary fires

- Response time of firefighters and emergency response personnel to secondary fires

Thus, a targeted risk analysis methodology is necessary to analyze these time-based variables.

Performing the RMV risk analysis is further complicated due to certain time-based variables being specific to the location of a potential rupture. Gas release behavior is influenced by site-specific pipe attributes and the consequences associated with thermal radiation from an ignited rupture would be based on the actual property located adjacent to the pipeline.

How does Dynamic Risk support operators in meeting regulatory requirements?

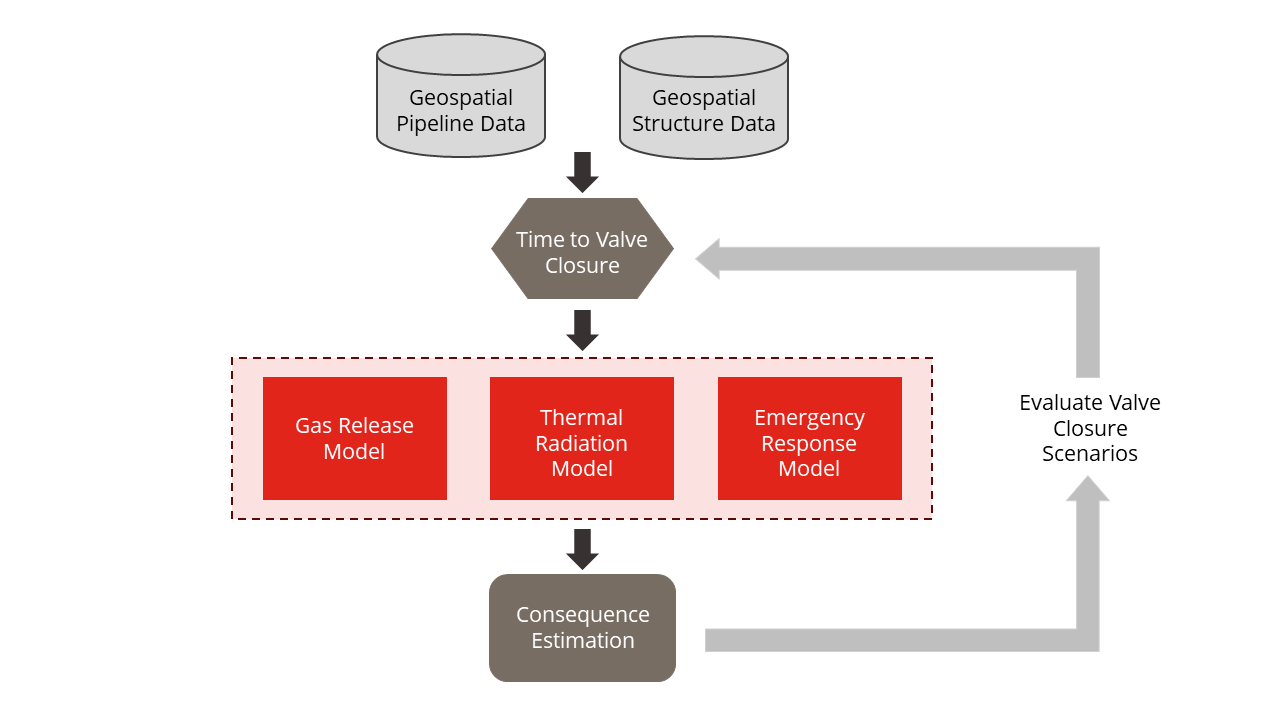

To help operators demonstrate compliance with 49 CFR 192.935(c) and support the annual certification of senior executives as per 49 CFR 192.935(f), Dynamic Risk developed a solution to evaluate the required factors in the regulations, the time-based variables, and the location-based variables. Effectively, the solution estimates potential building damage reduction in HCA segments with a rapid valve closure (utilizing RMV) in conjunction with fire-fighting efforts to extinguish secondary fires. A simplified framework of the RMV risk analysis solution is illustrated below.

Figure 1: Simplified Framework of RMV Risk Analysis Solution

The estimated cost resulting from potential property damage reduction in an HCA can then be compared with the costs of installing RMV in that area. This information can be used by operators to make informed decisions about whether RMV is an efficient means to protect an HCA.

White Paper: Rupture Mitigation – Risk Management and Regulatory Compliance Considerations for Pipeline Operators

Our white paper, authored by Curtis Parker, provides a risk management perspective to rupture mitigation, outlines the changes in PHMSA’s Gas Mega Rule, and identifies key considerations for pipeline operators in managing risk and complying with regulations.

Contact us for more information about how our team can help you addressing PHMSA’s requirements for Rupture Mitigation Valve Risk Analysis.

About the Author:

Curtis Parker, Principal Consultant

Curtis has over 20 years of experience in asset reliability management of energy infrastructure, including design, construction and operations of natural gas and liquid pipeline systems, and natural gas utilities. For one operator, he directed an integrity management organization responsible for over 19,000 miles of gas and hazardous liquid transmission pipelines across 30 US states, Canada, and Mexico. Curtis is a Professional Engineer and has hands-on expertise in risk assessment and integrity assessment methods, with extensive experience project management of field inspection, repair, and maintenance projects. He has led pipeline incident investigations and root cause analyses, and interfaced with regulators in managing return to service efforts.