Considerations for MAOP Reconfirmation of Facilities in PHMSA’s Gas Mega Rule RIN-1

The Pipeline and Hazardous Materials Safety Administration (PHMSA) has introduced the Gas Mega Rule, Parts I, II and III which are a comprehensive set of regulations that are aimed at enhancing pipeline safety and reliability. One critical component of Part I (RIN-1) is the requirement for Maximum Allowable Operating Pressure (MAOP) reconfirmation and material verification for certain gas transmission pipeline segments. This blog will focus on the applicability of RIN-1 requirements to gas transmission pipeline facilities.

Are Facilities included in PHMSA’s Gas Mega Rule MAOP Reconfirmation (MAOP-R) requirements in Part I (RIN-1)?

Indeed, certain facility pipe is included in the 49 CFR § 192.624 MAOP-R requirements introduced in the Gas Mega Rule Part I (RIN-1). Similar to transmission pipe, the requirements for MAOP-R of facility pipe are applicable if:

- Traceable, verifiable and complete (TVC) material and hydrostatic test records are not available, and

- Pipe is in a high consequence area (HCA), or

- Pipe is in a Class 3 or Class 4 location

- For “grandfathered” pipe [i.e., MAOP was established in accordance with 192.619(c)], TVC hydrostatic test records are not available, and

- Pipe is in an HCA, or

- Pipe is in a Class 3 or Class 4 location, or

- Pipe is in a moderate consequence area (MCA) that are piggable

For facility pipe that is deemed applicable based on the criteria above, MAOP-R is required up to the emergency shutdown valves (ESD) or isolation valves, and can involve various lengths of pipe depending upon the facility configurations. In general, most facility pipe is not piggable and, as such, MCA criteria would not typically apply.

It is also important to note that, outside of § 192.624 MAOP-R requirements, § 192.619 requires that Operators be capable of demonstrating how the original MAOP was established for pipe in all locations.

What are the key Gas Mega Rule MAOP-R considerations and similarities/differences from line pipe?

Similar to transmission pipe, § 192.624 provides for the application of one of several methods for MAOP-R of applicable facilities pipe including pressure test, pressure reduction, engineering critical assessment (ECA), pipe replacement and alternative technology. However, a comprehensive gas transmission pipeline system MAOP-R program should incorporate a facilities-specific strategy for defining the scope and priorities for facility pipe due to the unique assessment approaches, data availability and MAOP-R boundary requirements.

ECA in facilities will have certain challenges but is likely going to be a primary MAOP-R method as, in many cases, the associated outages of facilities in highly populated areas to perform hydrostatic testing or replacement is not feasible or practicable. Even beyond the capital costs, the sheer number of outages that would be required across an operating system to perform hydrostatic testing or replacement will make analysis of the pipe in-service a preferred approach.

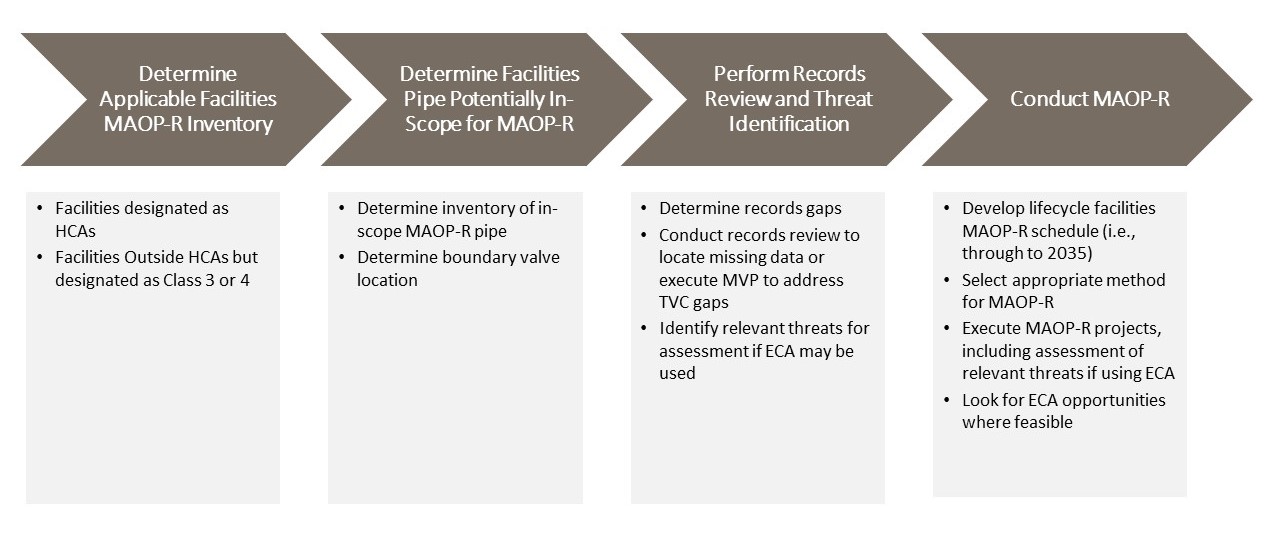

For these reasons, ECA is expected to be a key tool for MAOP-R of facilities pipe and components subject to § 192.624. Key elements of a facilities-specific MAOP-R strategy are outlined in Figure 1.

Figure 1 – Facilities Pipe MAOP-R Strategy

Assignment of class location has not been consistently practiced for facilities and much of this pipe does not exist in Geographic Information Systems (GIS). This is expected to present a significant challenge for pipeline Operators to identify applicable pipe. With respect to MAOP-R method selection, if ECA is the chosen method, in-line inspection (ILI) data is typically not available for this pipe, so Operators need to determine how to gather sufficient data to support an ECA.

What are some data and integrity assessment considerations for MAOP-R of facilities?

The integrity threats applicable in a facility, and that may require assessment to support MAOP-R, may be very different than transmission pipe as will the assessment methods that will be relied upon since the pipe is largely not piggable. Some threats, for example above ground painted pipe that operates at low stress, will not be susceptible to environmental cracking as there will not be a conducive environment. Certain threats may be justifiably removed from consideration based on susceptibility while other threats may require excavation and inspection using non-destructive evaluation (NDE) methods. It is also expected that certain operating and maintenance (O&M) required activities, such as visual atmospheric corrosion inspections for above ground pipe, can be leveraged for certain threats.

Conclusion

The RIN-1 MAOP-R and material verification requirements support improved safety and reliability for both pipelines and facilities. Operators need to consider project, technical, financial, and organizational factors when selecting methods for MAOP-R. The unique considerations and challenges around facilities integrity assessments and MAOP-R scope determination require a strategic approach.

Dynamic Risk supports our clients’ Gas Mega Rule integration and operationalization programs and brings the required expertise and rigor to ensure compliance to RIN-1 requirements for pipelines and facilities. This includes conducting gap assessments to Gas Mega Rule requirements, supporting process and procedure development, developing lifecycle compliance plans and strategies, and conducting ECAs.

Contact us for more information about how our team can help you implement PHMSA’s Gas Mega Rule at your organization.

About the Author:

Dan Williams, Principal Consultant / Client Lead

Dan Williams is a licensed professional engineer with a background in Materials Engineering and has over 30 years combined experience in pipe and tube manufacturing, pipeline integrity and pipeline risk management. Dan is a Principal Consultant / Client Lead at Dynamic Risk where he is responsible for providing technical and strategic leadership in pipeline engineering assessment and risk assessment solutions for both liquids and gas transmission pipeline operators in Canada and the United States. This experience has also included providing regulatory support to operators in these areas. Dan is also a member of the CSA Z662 Risk & Reliability Technical Sub-Committee.